Bypass Overview

Bypass Operations

Bypass Overview

Bypass Operations

Failing to gain confidence in general pump hire contractors to satisfy the sheer scale and stringent requirements for a project, it becomes evident, there is only one company in the country, with the agility, resources and commitment to manage the scope of any size project. Welltech has the technical team to carry out site investigation and will immediately deploy a team to provide a bypass solution, no matter how technically challenging.

Bypass Overview

Welltech’s Bypass Division specialises in the successful pumping and bypassing of sewer and waste water across the nation and internationally, incident-free. This division’s establishment has largely been advanced by an industry in dire need for a large scale operator with the unique capacity to manage flow rates in excess 14,000L/sec.

Being able to pump high flow rates is only the beginning. We understand and embrace that to successfully carry out large scale bypass operations, all details and possible scenarios must be identified and understood. Welltech’s Bypass Division ensures each project component is considered, planned and executed using the most advanced equipment and practices.

Our research and development team constantly source, test and develop the latest equipment and technology available around the world before we deem it a viable addition to our Bypass operations.

Clients understand that once the Welltech team have developed, endorsed and introduced a new product into the fleet, it is guaranteed to produce reliable, quality results.

Our Bypass Division ensures each project component is considered, planned, and executed using the most advanced equipment and practices to deliver incident-free, completely controlled Bypass solutions, every time.

When your next bypass project demands an innovative solution, offering the best equipment and a dedicated team, Welltech has you covered.

Bypass Project Scope

Bypass installation is just one part of a much larger project, and often design engineers aren’t trained in bypass design, fortunately, Welltech is. Welltech can not only provide high-quality equipment, we also have the engineering knowledge and installation expertise. Read our approach to planning and designing the perfect bypass system for your next bypass project - Welltech Bypass Project Scope.

Need a solution for your next by pass project? Complete our Bypass Project webform.

Luggage Point STP Bypass

Welltech’s expertise was called upon to facilitate the installation of permanent stopboards in the Luggage Point STP outfall channel

Fleet Of Equipment

Fleet of Equipment

Fleet Of Equipment

Fleet of Equipment

Fleet of Equipment

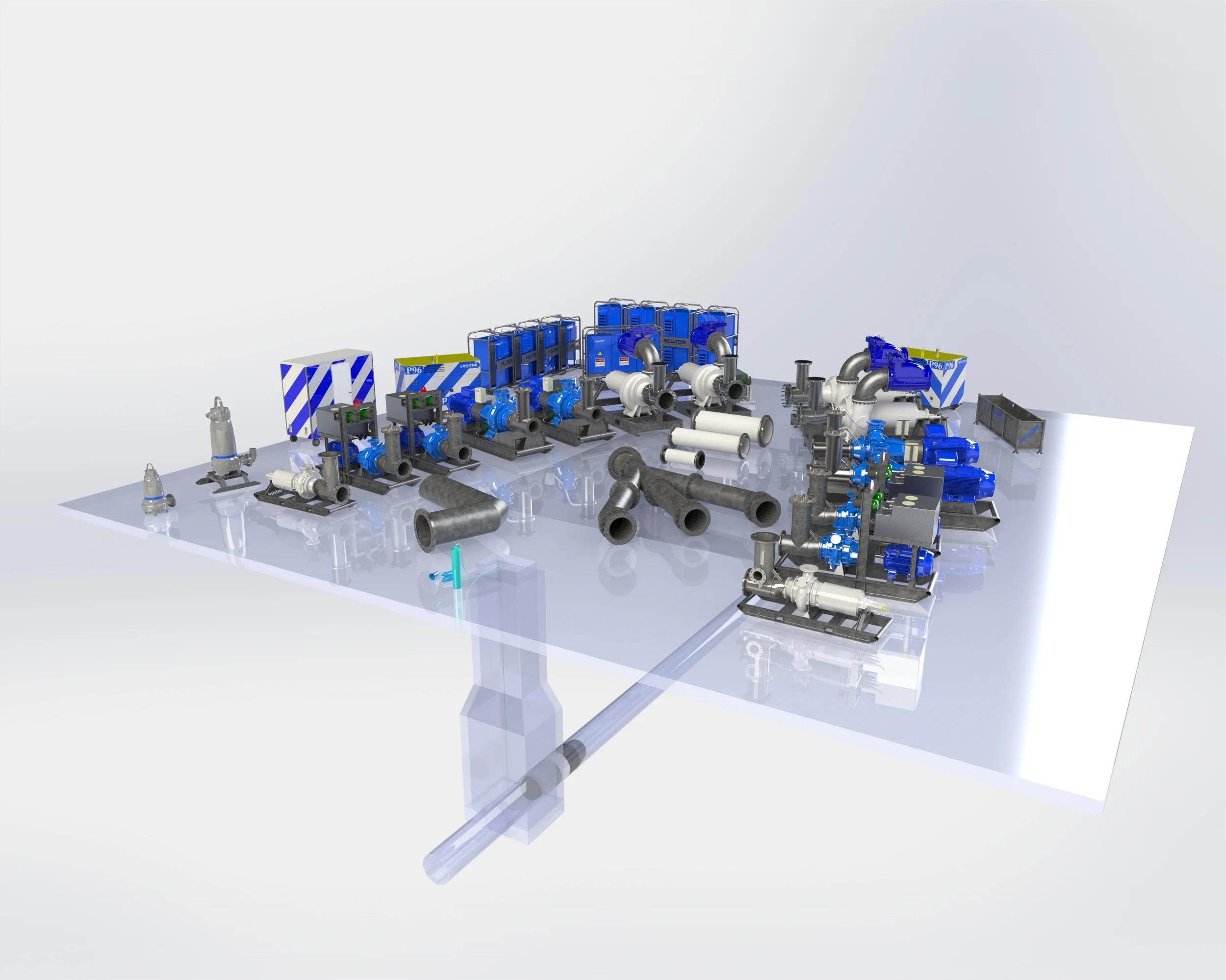

Welltech has the largest fleet of Hidrostal pumps in the world, and the capacity to pump in excess of 14,000L/sec.

Welltech is renowned for quality solutions, so after years of research into pumps, we have aligned ourselves with Hidrostal, world leaders in waste water pump design and reliability. The Hidrostal pumps have screw impeller geometry and free passage design that can handle objects and laden liquids especially those solids that are raggy and fibrous which are prevalent in domestic and industrial waste-water.

We have pumps capable of pumping from 12L/sec (piccolo) through to the newest addition to our fleet – il padrino.. The il padroni’s are capable of pumping individual flow rates in excess of 2,100L/sec.

Every pump in our fleet has an identical twin to act as its contingency backup.

Our fleet not only consists of pumps, we also have a vast range of the latest state of the art Variable Speed Drives (VSD) fitted with SCADA telemetry and alarm systems. These drives can be interfaced with all Water Authority’s control centers enabling complete clarity of site conditions at all times.

Some of our other equipment includes;

Magflo Flow Monitoring Spools

Valves and fittings

Custom, prefabricated temporary wet well pump stations

“I am proud to say Welltech have been voted Hidrostal Business Partner of the year. Well done and thank you for your outstanding support over the years.”

Once serviced and quality checked by our workshop team, all Welltech’s fleet of equipment will receive the tick of approval and be ‘Good to Go’. You can be assured, once 'Good to Go' it will be supported by Welltech’s guarantee of Commitment = Satisfaction.

Research & Development

Research &

Development

Research & Development

Research &

Development

Research & Development

Welltech have established a Research and Development program that constantly scours the world looking for and researching efficient and effective methods of Bypassing.

We believe that we have the largest capacity and most modern fleet of Bypass pumping equipment not only in Australia but in the World. All of our equipment is operated and supported by state of the art Variable Speed Drives (VSD) and ultrasonic level control all of which is interfaced with SCADA back to base telemetry.

Design

Design

Design

Design

Design

Welltech acknowledges and appreciates the complexities of delivering Bypass projects which are always of a highly sensitive nature. Welltech bring together our Management, Design and Engineering Teams to collaboratively analyse each project in detail.

With all potential projects, our in-house drafting division first prepare 3D dimensional layout images which provide ourselves and our clients a clear understanding of exact setup, footprints and layouts onsite.

On the award of a project, our drafting team further produce detailed P&ID’s, material take off lists, site layout plans and fabrication drawings for all items. Our Design Team ensure our clients understand exactly how and what the site will look like once the system has been installed.

Fabrication

Fabrication

Fabrication

Fabrication

Fabrication

Welltech’s in-house 3D Design and Fabrication facility has the ability to build custom pipe spools, pump assemblies and any components required for our Bypass operations.

Our world class facility merges the best people with the best equipment which in turn produces consistently superior results. This compliments our philosophy of keeping a tightly controlled system that produces exacting standards on stringent lead times.

This we believe is a necessary component of delivering accurate and timely Bypass projects every time.

Compliance

Compliance

Compliance

Compliance

Compliance

Our Team produces documentation covering all aspects of every project. These documents include but are not limited to:

Concise Flow Management Plans

HSE Management Plans

Mechanical Checklists

Electrical Checklists

Design Drawings and Pump Analysis

Site desktop analysis such as DBYD reviews

Welltech ensures at the planning stage the project deliverables comply with the client’s requirements whether it is regulatory and/or legislative obligations.

Our compliance not only satisfies the documentation deliverable but also ensures that we maintain an impeccable quality control process across all projects.

Health, Safety and Environment

Health, Safety and Environment

Health, Safety and Environment

Health, Safety and Environment

Health, Safety and Environment

Due to increased demand surrounding health and safety issues in the workplace our HSEQ team ensure accurate and comprehensive Health, Safety and Environmental procedures are produced and implemented onsite.

These documents can include but are not limited to the following:

SWMS

Take 5’s

Risk and Environmental Analysis and Plans

In The Event of Alarm Procedures

Accident and Incident Reporting

Our HSEQ team ensure all personnel, equipment and sites are protected and safe at all times. All documentation is fully compliant and up to date with the latest legislative requirements.

Project Delivery

Project Delivery

Project Delivery

Project Delivery

Project Delivery

At Welltech we build strong relationships with our clients from inception to completion of all projects. At Welltech, ‘solutions’ is the key word, we will find a solution no matter what the issue.

The unwavering dedication of our team drives us relentlessly towards the ever moving goal of absolute perfection.

We will always deliver, on every promise we make, Guaranteed.

“The installation of the temporary stopboard gate 1 was successful and was a tribute to the planning and hard work from all those involved. Thanks to Zak Haines and the Welltech crew for assisting in proactive and precise planning.”

Bypass Projects

Projects

Bypass Projects

Projects

Project Success

In recent years, Welltech’s Bypass Division has carried out Australia’s largest sewer Bypass operations, all of which have been 100% incident free.

Below is a small selection of various size projects undertaken in Queensland, Melbourne, Perth and Brisbane:

Luggage Point STP Outfall Channel, Client: Fulton Hogan Utilities, Flows: up to 2,700L/sec, Duration: 6 days. A total of 580 million litres were successfully pumped over the 6 days. 100% incident free bypass pumping. Read the detailed project overview.

North Yarra Main Sewer Bypass, Client: John Holland KBR JV, Flows: up to 2,100L/sec, Duration: 120 days. 100% incident free bypass pump. Read the detailed project overview.

Glenelg WWTP High Flow Emergency Bypass, Client: Fulton Hogan/SA Water, Flows: up to 1,500L/sec, Duration: 8 months. A grand total of 8,678,000,000 litres pumped, equivalent to 3,471 Olympic swimming pools. 100% incident free bypass pumping. Read the detailed project overview.

Woolloongabba Main Sewer Replacement, Client: John Holland/QUU, Flows: up to 1,650 L/sec, Duration: 424 days across 25 locations. 100% incident free bypass pumping. Read the detailed project overview.

Hobsons Bay Main Sewer Bypass, Client: John Holland KBR JV, Flows: up to 400L/sec, Duration: 126 days. 100% incident free bypass pumping. Read the detailed project overview.

Dianella Main Sewer Bypass, Client: Water Corporation, Flows: up to 790L/sec, Duration: 154 days. 100% incident free bypass pumping. Read the detailed project overview.

Woogaroo Trunk Main Sewer Refurbishment, Client: Thiess/ Queensland Urban Utilities, Flows up to 1,150L/sec, Duration: 98 days. 100% incident free bypass pumping. Read the detailed project overview.

Shenton Park Scheduled Bypass, Client: RCR Water/Water Corporation, Flows: up to 1,600L/sec, Duration: 3 months. Over 5,500 man-hours including installation, commissioning and 24/7 operation. 100% incident free bypass pumping. Read the detailed project overview.

Melbourne Main Sewer, Client: John Holland/Melbourne Water, Flows: up to 1,000 L/sec, Duration: over 500 days. 100% incident free bypass pumping.

Pascoe Vale Main Sewer, Client: John Holland/Melbourne Water, Flows: up to 1,300 L/sec, Duration: 70 days, 100% incident free bypass pumping.

Click here to view our gallery of projects

Welltech Lampe Pipe Plugs

Lampe Pipe Plugs

Welltech Lampe Pipe Plugs

Lampe Pipe Plugs

Lampe Pipe Plugs

Welltech is renowned for quality solutions, so after many years of research into pipe plugs we have aligned ourselves in partnership with one of the world’s best manufacturers, LAMPE GmbH.

As the exclusive Australian national distributor, we are proud to offer a full inventory of these world leading pipe plugs.

Why Lampe Pipe Plugs:

• No manhole access required, simply lower, float into the pipe and inflate;

• No additional bracing necessary;

• Suited to all pipe cross sections from round pipes to oval, kite and throat profiles, open top and box profiles, even as far as rectangular box curvets;

• Made of neoprene rather than rubber, these plugs provide an extremely long service life compared to conventional pipe plugs;

• One device, many different diameters - 150mm up to 3,600mm;

• Repairable and reusable unlike most conventional pipe plugs once damaged in most cases cannot be used again;

• Lightweight and compact design making them easily folded and handled into all access chambers;

• Regarded as the safest and most economical pipe plug when compared to conventional stretchable pipe plugs or bladders;

• Our fast, highly skilled teams are available to mobilise our in-house fleet at a moment’s notice.

Click the image below to see this revolutionary plug in action…

Contact Welltech at anytime to discuss stock, pricing and the suitability of these revolutionary pipe plugs to suit your requirements.

Bypass Project Scope

Bypass Project Scope

Bypass Project Scope

Bypass Project Scope

Welltech is your partner that can not only provide high quality equipment, but engineering knowledge and installation expertise too.

To enable us to define the scope, and design a solution for your next bypass project, please complete the following: